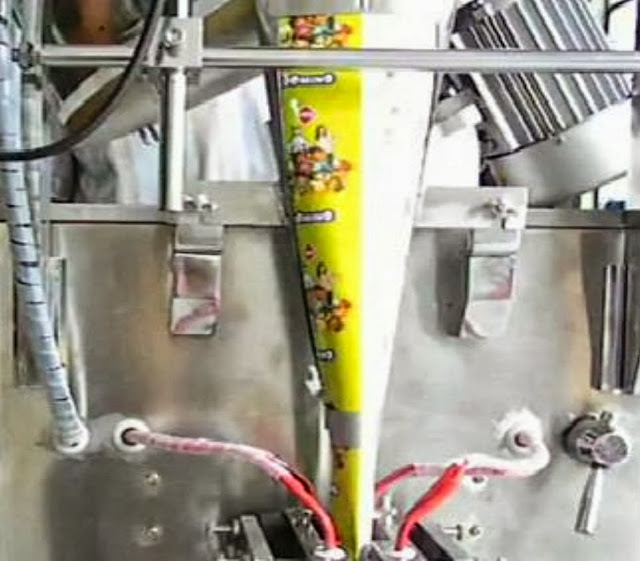

We Offer High speed Multi Track & Single Track Packing machines for Shampoo packaging application.

Our Range of High Speed Multi Track Shampoo Packing Machines are suitable to pack small shampoo sachets up to 200ML along with packaging speed up to 1000 sachets per minute passed up on dimension of sachet.

Our Single Track collar type- 400L Shampoo Packing Machine is suitable to pack large shampoo pouches up to 1000ML along with packaging speed up to 30 Pouches per minute based up on dimension of pouches.

The machines offered by US most preferred by industrial units for supporting their involved packaging process, the machine's superior performance in terms of filling, sealing, as well as other sub-processes that are part of packaging has allowed the company to gain due industry recognition and match up with the emerging Shampoo sachet packaging machine's demands in the packaging industry. Further, the company's expertise lies in offering these precision designed packaging machinery solutions in different finish forms.

The rich experience of us also lies in offering these Shampoo packaging machines in custom made finishes so as to perfectly suit specific process application requirements at client's end. Here, the effective use of quality components as well as perfect workmanship standards also makes these Shampoo sachet packaging machines gain high recognition as efficient performers with less maintenance requirements.

With gained experience and expertise, our factory offers these Shampoo Packing Machines in different model options to match up with specific packaging process needs of clients. Having automated operations, these machines help in cutting down the wear, & tear costs as well as ensure offered operations deliver precision sealing and high functionality standards. With all fabricated material extensively tested on different parameters before being put to use, the superior engineering standards of these machines and their availability in multi track modes make them highly preferred and demanded in the market.

Technical parameter of single track shampoo bag packing machine:

Max film width 320mm Film thickness 0.05-0.08mm Filling range 10-400ml

Bag-packing length 20-200mm Bag-packing width 10-150mm

Packing speed 10-40bags/min Dimension 980*680*1650mm

Power 2kw 220v Weight 350kg

Optional fittings for shampoo packaging machinery:

1.Ribbon printer

2.Hole punch device

3.Bag linking device

4.Air compressor

Our factory since 1992 has been manufacturing the cosmetic&food making and packaging machinery.In these field we have the experience rich enough to solve the questions encountered by our customers from both home and abroad.For more information about high quality machinery such as machines d'emballage de shampooing liquide,please email via jackdu999@yahoo.com or browse our website www.cosmeticsmachinery.blogspot.com plus http://youtube.com/user/mrjackdu007

Follow us on twitter:http://www.twitter.com/jackdu007

Like us on facebook:http://www.facebook.com/jackdu999

Skype us by :turnanewleaf

Mobile:+86-1581188-2441

.jpg)

.jpg)